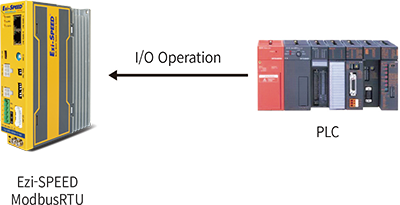

- 1. RS-485 based Modbus-RTU Control

-

Ezi-SPEED Modbus-RTU supports the Modbus-RTU protocol based on RS-485 communication. This enables application in both input / output signal control and RS-485-based control systems.

Modbus operates in a single-master / multi-slave configuration, where only the master can send commands, and each slave responds after executing the commands. PLC, HMI, PC can function as modbus client(master) and control the system via RS-485 serial communication.

- A single master controller can connect with up to 31 slaves(drives). The master controller can send commands to either a single slave or multiple slaves simultaneously

- 2. BLDC Motor Unit

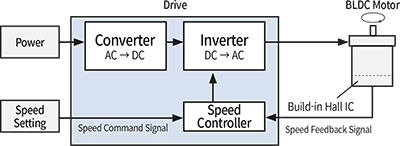

- A conventional DC motor rotates using brushes and a commutator, requiring regular maintenance. In contrast, a BLDC (Brushless DC) motor operates without mechanical contacts, utilizing a semiconductor-based drive circuit, resulting in a longer lifespan and reduced maintenance requirements. Embedded permanent magnets in the rotor enhance efficiency, while automatic motor current control ensures consistent torque characteristics across all speed ranges. Additionally, utilizing Hall IC for feedback control allows precise speed regulation from low to high speed.

< Control Block Diagram >

-

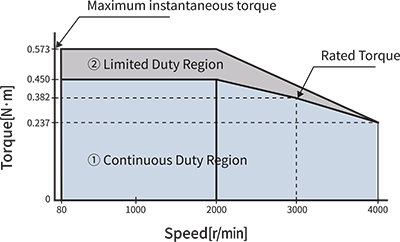

The BLDC motor can operate continuously with a constant torque from low speeds to its rated rotational speed. Within the rated torque range, it maintains a stable rotational speed even when the load varies.

BLDC motors have two operating regions: continuous duty region (①) and limited duty region (②). The limited duty region is used for acceleration torque when starting an inertial load. However, operating in this region more than 40s activates the built-in overload protection function, which automatically prevents overheating of the motor and drive.

< Example of Torque Characteristics According to Speed of BLDC Motor >

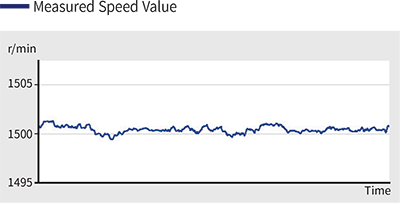

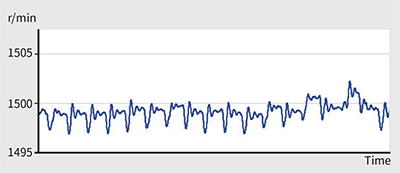

- 3. High Precision Speed Control (Speed Regulation ±2%)

- Ezi-SPEED compares the setting speed with the speed feedback signals from the motor at all time, and adjusts the motor current using vector control algorithm. So, even if the load changes, stable rotation is maintained from low speed to high speed. Inverter-controlled AC induction motor does not perform feedback control, so the speed will be reduced significantly when load increases. Ezi-SPEED is recommended for applications that require stable speed.

Ezi-SPEED 120W

Inverter + AC Induction Motor 100W

- • Load Factor: 95%

• Setting Speed : 1,500 r/min

• Resolution of External Encoder for Measuring Velocity Ripple: 32,000 P/R

- 4. Wide Speed Control Range (Speed Ratio: 1:80)

- Ezi-SPEED has wide speed control range compared to AC induction motor with inverter. Because torque is not restricted at low speed, Ezi-SPEED is recommended for application that requires stable torque over from low to high speed.

-

Product Speed Control Range[r/min] Speed Ratio Ezi-SPEED 50 ~ 4,000 1:80 Inverter + AC Induction Motor 200 ~ 2,400 1:12 - • Speed range of Inverter + AC Induction Motor varies depending on model type.

- 5. Compact / Light Weight / High Power /High Efficiency

-

Unlike AC induction motors, BLDC motors use permanent magnets in the rotor so that it could prevent secondary loss from rotor.

Therefore, BLDC motors has higher efficiency than invertercontrolled AC induction motor so that customers can save energy.

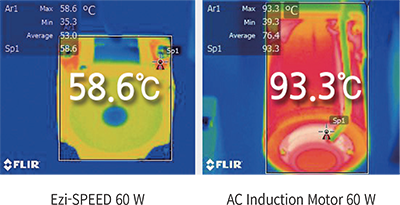

- Comparison of motor temperature after 4 hours continuous operation when load factor is 100% and Setting speed is 1,500 r/min.

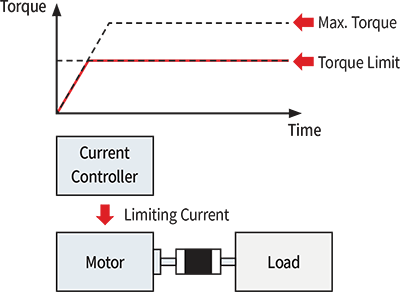

- 6. Torque Limit Function

- Ezi-SPEED can control the torque limit by limiting the current flowing through the motor. Torque limit function can be used to prevent excessive force.

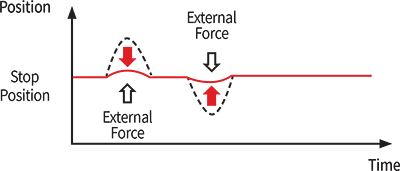

- 7. Load Holding Function

- Load holding function can be used for an electrical retention brake at stop without the need for a mechanical brake. So, this function is suitable for applications that perform work while stopping the transportation conveyors.

- 8. Operation by External I/O

- A controller, such as a PLC, can perform operations such as starting, stopping, changing the direction of rotation and multi-speed operation by connecting external I/O. Additionally, the speed can be adjusted using analog input by connecting a potentiometer.

- 9. 16-Speed Settings

- 16-speed operation can be done by setting operation data No. 0 to No. 15. Operation data can be configured using Ezi-SPEED Setting program or through RS-485 communication.

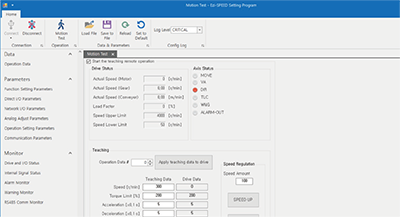

- 10. Ezi-SPEED Setting program

-

Ezi-SPEED EtherCAT can perform various functions using the separately provided Ezi-SPEED Setting program.

• Parameter Setting Function: Easily modify and save various parameters.

• Monitoring Function: Easily monitor the internal status of the drive and motor, including speed, load factor, I/O signals, alarms, and warnings.

• Testing Function: Easily test whether the drive and motor are operating correctly.

- 11. Protection Function

-

• Ezi-SPEED detects abnormal situations like overload, over voltage etc. When this happens, the operation is stopped and alarm is displayed.

• A regenerative resistor can be used when the deceleration time is short or when the large inertia load is used. Also the protection function can be activated for the excessive external force acting on the motor shaft.